Auto Parts Test Equipment ISO 16750 Ice Water Shock Test For

Electronic Components

Standard:

VW-80000 Electric And Electronic Components In Motor Vehicles up to

3.5t General Requirements, Test Conditions and Tests clause 9.12

K-12 Temperature Shock With Splash Water;

ISO16750-4 Road vehicles-Environmental conditions and testing for

electrical and electronic equipment-Part 4: Climatic loads clause

5.4.2 Ice water shock test.

Purpose:

This test simulates a thermal shock induced by ice water and

applies to products in the splash areas of the vehicle. The purpose

of this test is to simulate ice water splashing over a hot

system/component. This happens when driving on wet roads during the

winter. Failure modes are mechanical cracking of materials or seal

failures caused by different temperature expansion coefficients. Auto Parts Test Equipment

Test method:

Splash water test:

Heat the DUT in a hot air oven at T max for the specified holding time, t h . Then splash the DUT with ice water for 3 s.

If the DUT is splashed in the vehicle from only one direction,

splash it from this direction only while it is in an as-installed

position. If the equipment is splashed from various directions in

the vehicle, then these directions shall be taken into account. In

this case, use a new DUT for each splash direction. The width of

the splash directed at the DUT shall always be greater than the

width of the DUT. If the DUTs to be splashed prove too big for one

jet, arrange several jets in a row to produce a line of splash

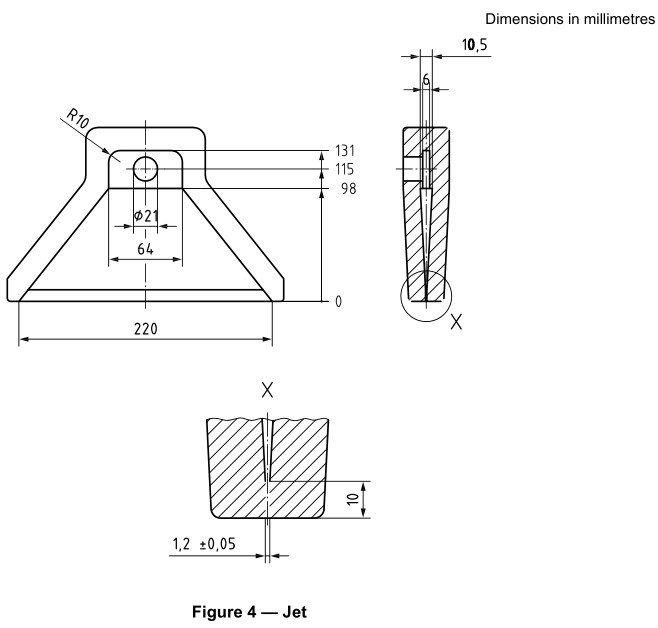

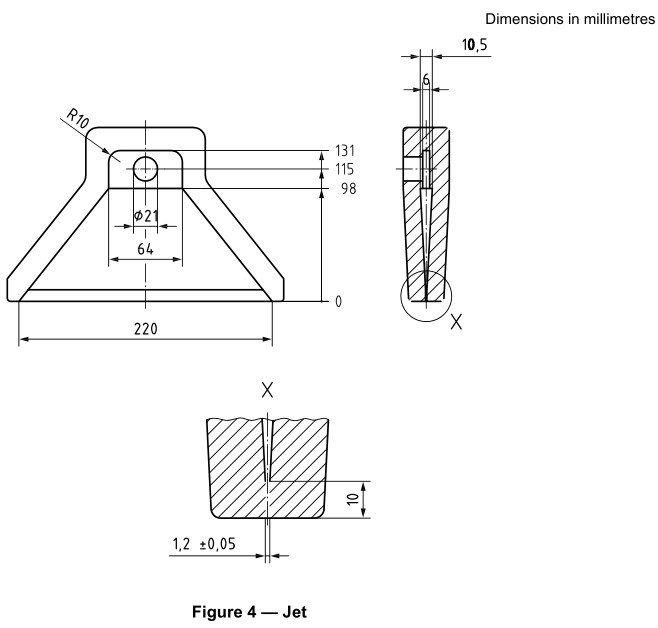

impact on the DUT. See Figures 4 to 6.

Test parameters include:

⎯ number of cycles: 100;

⎯ holding time, t h , at T max : 1 h or until DUT temperature stabilization is reached;

⎯ transition duration: < 20 s (for manual transition of DUT

between temperature storage and splashing);

⎯test fluid: de-ionized water;

⎯ water temperature: 0 °C to +4 °C;

⎯ water flow: between 3 l and 4 l per 3 s (splash duration);

⎯ distance between jet and DUT surface: (325 ± 25) mm (water shall

be applied over the complete width of the DUT);

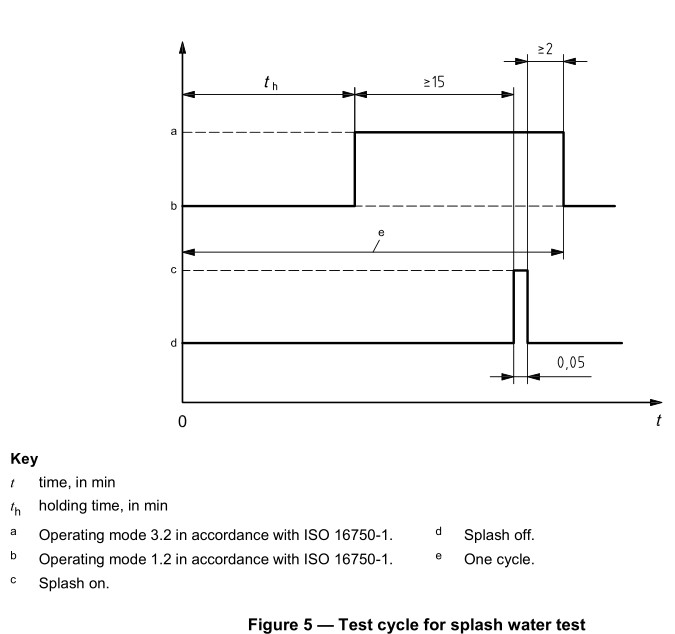

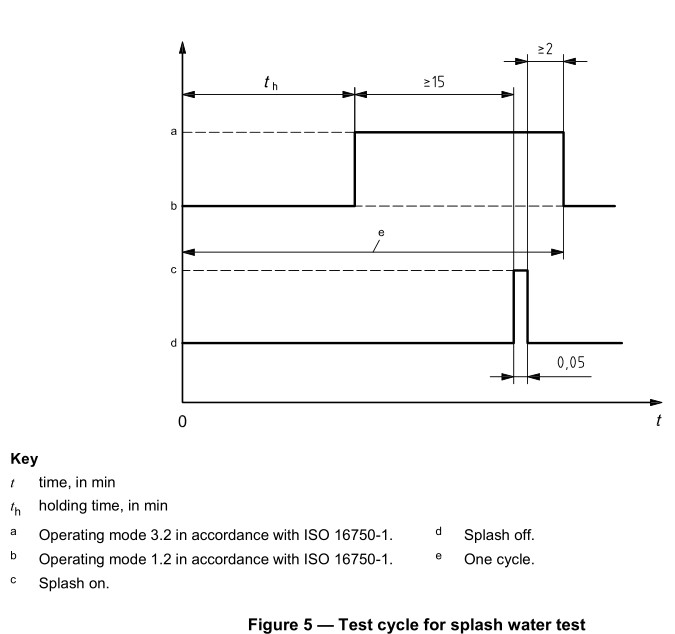

⎯ operating modes: see Figure 5;

⎯ orientation of the DUT: as in the vehicle.

Parameter:

| Inner size | 1000*1050*1080mm (D*W*H) Auto Parts Test Equipment |

| Temperature range | RT+10°C -160°C |

| Heating rate | RT+10°C -160°C<40min |

| Test fluid | de-ionized water |

| Volume of water tank | About 100L (Motor stirring, bottom slope, easy to clean and drain) |

| Water temperature range | 0-4°C |

| Cooling rate | The temperature should be stable at 2℃ in 30 minutes and 160℃ in

the test chamber |